Plant and Equipment Risk Assessment (PERA) for Padfoot Rollers

Ensure Safety and Compliance with Our Comprehensive PERA

We understand the importance of maintaining safety standards in the workplace, especially when operating heavy machinery like padfoot rollers. Our Plant and Equipment Risk Assessment (PERA) provides a detailed analysis of potential hazards associated with padfoot roller operations, ensuring that you are fully compliant with industry regulations and that your team remains safe.

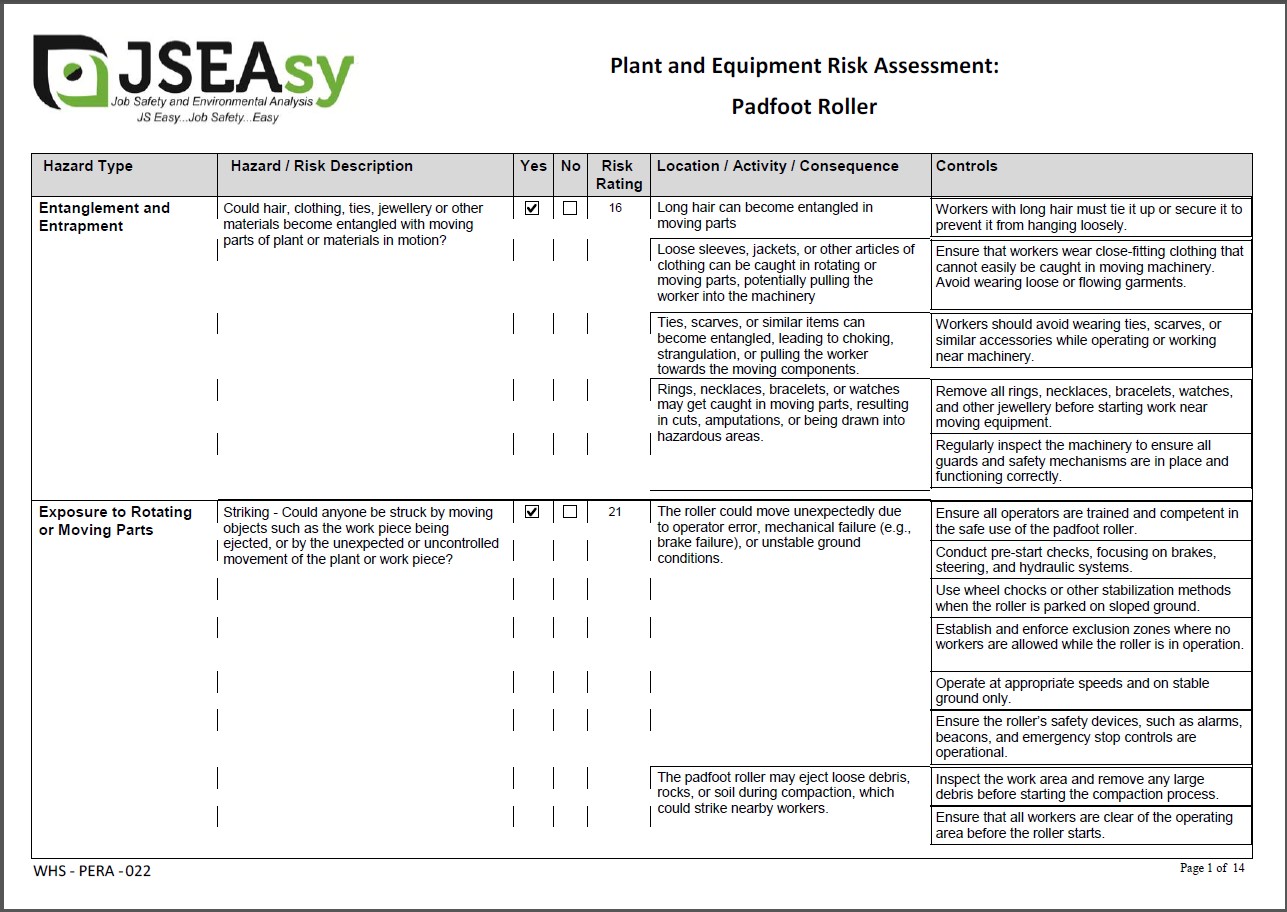

This risk assessment covers the safe operation and maintenance of a padfoot roller, commonly used in compaction tasks on construction sites. It includes the identification of hazards, potential risks, control measures, and responsibilities to ensure the safety of operators and other workers on site.

Why Choose Our PERA for Padfoot Rollers?

Comprehensive Hazard Identification

Our PERA identifies and assesses a wide range of hazards associated with padfoot roller operations, including:

- Entanglement Risks: Assessing potential entanglement of hair, clothing, or jewelry with moving parts.

- Striking Hazards: Evaluating the risk of being struck by moving objects or unexpected plant movements.

- Crushing and Pinching: Analyzing risks of crushing or pinching due to falling objects or moving parts.

- Soil Contamination: Identifying potential soil contamination from spills or improper waste disposal.

- Environmental Impact: Addressing potential impacts on local flora and fauna.

Tailored Control Measures

We provide effective control measures for each identified hazard, including:

- Maintenance and Inspections: Regular checks to prevent leaks and spills.

- Proper Waste Management: Guidelines for the disposal of hazardous materials.

- Erosion Control Techniques: Measures to minimize sediment runoff and protect waterways.

- Training and Awareness: Ensuring all personnel understand the importance of safety protocols.

Benefits of Using JSEAsy’s PERA

- Enhanced Safety: Our PERA minimizes risks associated with padfoot roller operations, promoting a safer work environment for all employees.

- Regulatory Compliance: Stay compliant with local, state, and federal regulations regarding heavy machinery operation and environmental protection.

- Improved Efficiency: By identifying hazards and implementing control measures, you can streamline operations and reduce downtime.

- Peace of Mind: Trust our expertise in risk assessments to protect your team and your business.

“JSEAsy’s Plant and Equipment Risk Assessment has transformed the way we operate. The comprehensive analysis and actionable recommendations have greatly enhanced our safety protocols!”

– Mark T., Construction Site Manager

“Thanks to JSEAsy, we’re confident that we’re meeting all regulatory requirements while ensuring the safety of our team.”

– Sarah K., Safety Officer

Why Choose This Standalone PERA?

- Peace of Mind – Developed by WHS professionals to industry standards

- Instant Download – Access the document immediately

- Generated using the JSEAsy EHS Software – Seamlessly integrates into your Safe Work Method Statement (SWMS) library

- Saves Time – No need to write a risk assessment from scratch

Who Is This For?

This PERA is ideal for:

- Building Contractors

- Civil contractors

- Mining operations

- Subcontractors

- Hire companies

Document Format:

- Delivered in PDF format. We can add your logo and details of a particular make and model at no additional cost.

- Fully printable

- Includes risk matrix and risk ratings

Why do you need a PERA?

Under Australian WHS laws, employers and contractors are required to identify and manage risks related to plant and equipment. Padfoot Rollers carry notable dangers due to their mechanical parts, and the environments in which they operate.

The requirements are outlined in the Managing risks of plant in the workplace code of Practice.

This PERA helps ensure your team works safely and your business remains compliant and audit-ready.

Ensure safety, compliance and peace of mind — in minutes, not hours.

With JSEAsy Plant & Equipment Risk Assessment Software, you can instantly generate WHS-compliant risk assessments, link them with SWMS and SOPs, and centralise all your plant registers and maintenance schedules. Designed for businesses managing any scale of machinery—from a single tool to full fleets—JSEAsy streamlines your safety workflows, reduces errors from paperwork, and keeps you audit-ready at all times

Need more than one PERA or other Safety Documents?

The JSEAsy EHS Software takes your safety management to the next level—allowing you to create, manage, and update SWMS, risk assessments, and other safety documentation all in one central platform. With built-in templates, version control, and cloud-based access, it’s designed to save time, improve consistency, and help your business meet ongoing WHS obligations with ease.

Key Features of JSEAsy Software

Preloaded SWMS, SOPs and Risk Assessments

Access a vast library of ready-to-use templates across construction, maintenance, and high-risk industries.- Fully Editable Templates

- Safe Work Method Statements (SWMS)

- Plant and Equipment Risk Assessments

- Safe Operating Procedures

Centralised Safety Documentation

Keep all your safety documents in one secure place—easily accessible on desktop or cloud (depending on plan).Project-Specific Job Packs

Automatically generate full WHS job packs including SWMS, risk assessments, training records, permits, and sign-off sheets.Version Control and Auto Updates

Maintain consistency and compliance as templates are updated with regulation changes.Staff and Contractor Management

Track inductions, licences, and competencies—ideal for small teams or larger subcontractor networks.Simple Interface

Intuitive menus and guided workflows make it usable even by those with limited admin or computer experience.Multi-user Access (Multiuser and Premium Version)

Collaborate across your team or sites with secure role-based access.