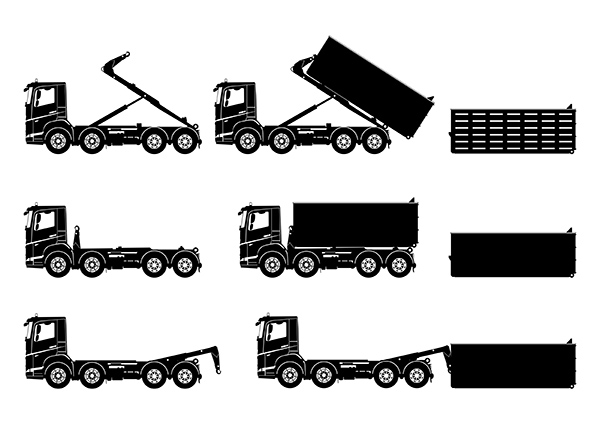

Hook-Lift Truck Plant and Equipment Risk Assessment (PERA)

This plant and equipment risk assessment for Hook-Lift trucks, specifically designed for collecting roll on/off bins has been created using the JSEAsy EHS Software. Safety is our top priority, and JSEAsy is dedicated to helping you understand the risks associated with operating Hook-Lift trucks and how to mitigate them effectively.

Identifying Hazards

To ensure a thorough assessment, we need to identify potential hazards associated with Hook-Lift trucks:

- Operational Hazards: Risks during truck operation, such as tipping over, collisions, and mechanical failures.

- Loading and Unloading Hazards: Risks associated with loading and unloading roll on/off bins, such as bin instability, uneven loads, and falling bins.

- Maintenance Hazards: Risks during maintenance activities, including exposure to hazardous materials, working in confined spaces, and using heavy tools.

- Environmental Hazards: Risks from environmental conditions, such as adverse weather, uneven terrain, and restricted operating spaces.

- Human Factors: Risks related to human error, inadequate training, fatigue, and non-compliance with safety protocols.

Assessing the Risks

Once hazards are identified, the next step is to assess the risks:

- Severity: Evaluate the potential impact of each identified hazard (e.g., minor injury, major injury, fatality, environmental damage).

- Likelihood: Determine the probability of each hazard occurring (e.g., rare, unlikely, possible, likely, almost certain).

- Risk Rating: Combine severity and likelihood to assign a risk rating (e.g., low, medium, high, extreme).

Implementing Control Measures

To mitigate identified risks, implement the following control measures:

- Elimination: Remove the hazard entirely if feasible (e.g., using different equipment).

- Substitution: Replace the hazard with a less dangerous alternative (e.g., smaller bins).

- Engineering Controls: Modify equipment or the environment to reduce risk (e.g., installing safety interlocks, improving stability mechanisms).

- Administrative Controls: Establish procedures and policies to mitigate risks (e.g., operator training, routine maintenance schedules, site-specific safety protocols).

- Personal Protective Equipment (PPE): Provide and enforce the use of appropriate PPE (e.g., hard hats, high-visibility vests, safety boots).

Monitoring and Reviewing

Continuous monitoring and regular reviews are crucial for maintaining safety:

- Regular Inspections: Conduct routine checks of the Hook-Lift truck and associated equipment to ensure they are in good working condition.

- Incident Reporting: Encourage the reporting of near-misses, incidents, and hazards to continually improve safety measures.

- Review and Update: Periodically review and update the risk assessment to reflect any changes in operations, equipment, or regulations.

Specific Considerations for Hook-Lift Trucks

- Loading and Unloading Procedures: Follow proper procedures to prevent overloading, uneven loads, and spillage.

- Stability: Monitor and control factors affecting the stability of the truck, particularly when loading or unloading bins.

- Site Conditions: Assess the operating environment for hazards such as steep gradients, soft ground, or obstacles.

- Maintenance Program: Implement a maintenance program that includes regular checks on hydraulics, brakes, tires, and other critical components.

- Operator Training: Ensure all operators are adequately trained and competent in using the Hook-Lift truck safely and effectively.

- Emergency Procedures: Establish and communicate emergency procedures for situations such as tip-overs, mechanical failures, or accidents.

Conclusion

Conducting a thorough risk assessment for Hook-Lift trucks is essential for ensuring safety and preventing accidents. By identifying hazards, assessing risks, implementing control measures, and continuously monitoring and reviewing, you can create a safer working environment for everyone involved in the operation of Hook-Lift trucks.

For more information or assistance with your risk assessment, please contact our safety team. We’re here to help you maintain the highest standards of safety in your operations.

Why Choose This Standalone PERA?

- Peace of Mind – Developed by WHS professionals to industry standards

- Instant Download – Access the document immediately

- Generated using the JSEAsy EHS Software – Seamlessly integrates into your Safe Work Method Statement (SWMS) library

- Saves Time – No need to write a risk assessment from scratch

Who Is This For?

This PERA is ideal for:

- Building Contractors

- Civil contractors

- Mining operations

- Subcontractors

- Hire companies

Document Format:

- Delivered in PDF format. We can add your logo and details of a particular make and model at no additional cost.

- Fully printable

- Includes risk matrix and risk ratings

Why do you need a PERA?

Under Australian WHS laws, employers and contractors are required to identify and manage risks related to plant and equipment. Hook-Lift Trucks carry notable dangers due to their load handling, mechanical parts, and the environments in which they operate.

The requirements are outlined in the Managing risks of plant in the workplace code of Practice.

This PERA helps ensure your team works safely and your business remains compliant and audit-ready.

Ensure safety, compliance and peace of mind — in minutes, not hours.

With JSEAsy Plant & Equipment Risk Assessment Software, you can instantly generate WHS-compliant risk assessments, link them with SWMS and SOPs, and centralise all your plant registers and maintenance schedules. Designed for businesses managing any scale of machinery—from a single tool to full fleets—JSEAsy streamlines your safety workflows, reduces errors from paperwork, and keeps you audit-ready at all times

Need more than one PERA or other Safety Documents?

The JSEAsy EHS Software takes your safety management to the next level—allowing you to create, manage, and update SWMS, risk assessments, and other safety documentation all in one central platform. With built-in templates, version control, and cloud-based access, it’s designed to save time, improve consistency, and help your business meet ongoing WHS obligations with ease.

Key Features of JSEAsy Software

Preloaded SWMS, SOPs and Risk Assessments

Access a vast library of ready-to-use templates across construction, maintenance, and high-risk industries.- Fully Editable Templates

- Safe Work Method Statements (SWMS)

- Plant and Equipment Risk Assessments

- Safe Operating Procedures

Centralised Safety Documentation

Keep all your safety documents in one secure place—easily accessible on desktop or cloud (depending on plan).Project-Specific Job Packs

Automatically generate full WHS job packs including SWMS, risk assessments, training records, permits, and sign-off sheets.Version Control and Auto Updates

Maintain consistency and compliance as templates are updated with regulation changes.Staff and Contractor Management

Track inductions, licences, and competencies—ideal for small teams or larger subcontractor networks.Simple Interface

Intuitive menus and guided workflows make it usable even by those with limited admin or computer experience.Multi-user Access (Multiuser and Premium Version)

Collaborate across your team or sites with secure role-based access.