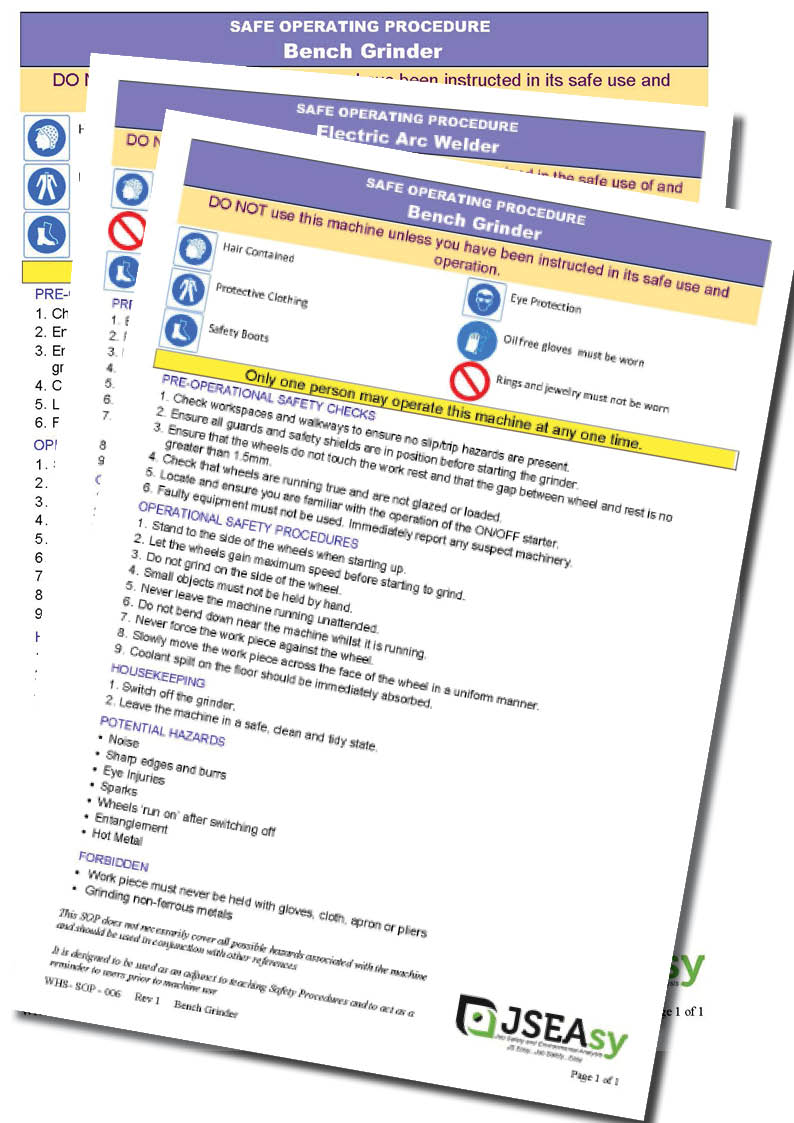

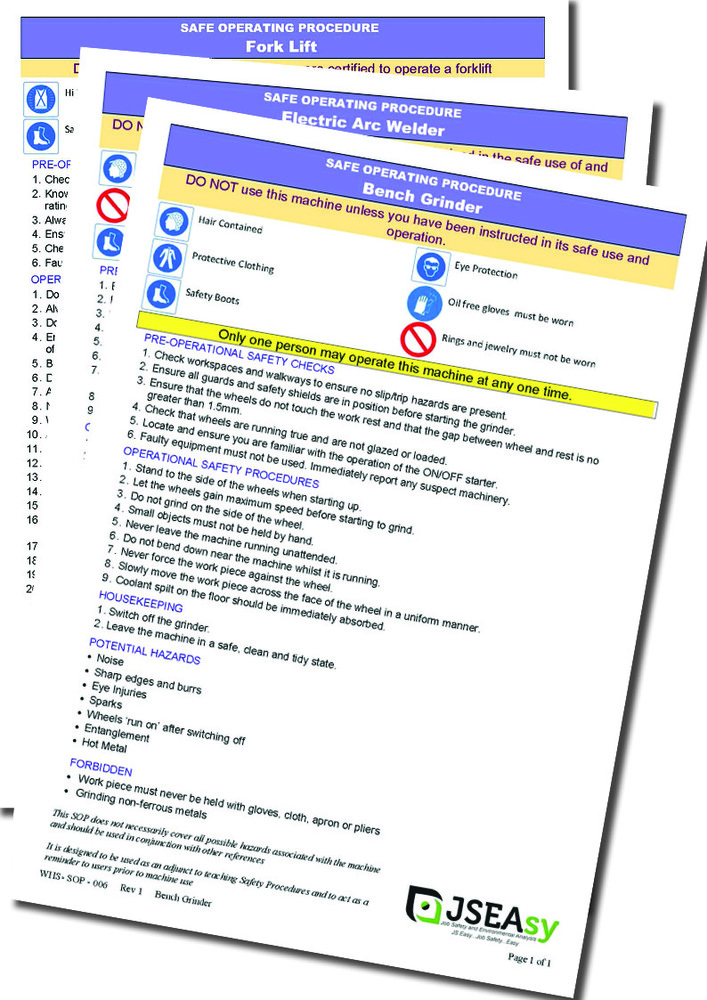

Bench grinders are powerful tools with rapidly rotating wheels, which can cause severe injuries if not used correctly. An SOP ensures that operators are aware of the correct procedures, such as how to properly secure workpieces, wear appropriate personal protective equipment (PPE), and avoid common hazards like flying debris or wheel bursts.

Protecting the Operator:

The SOP includes guidelines on the necessary safety gear, such as safety glasses, face shields, gloves, and hearing protection. It also outlines the importance of maintaining a safe distance from the grinder and ensuring that guards are in place, reducing the risk of injury.

Ensuring Proper Use and Maintenance:

A well-defined SOP helps users understand the correct way to operate the grinder, including the importance of using the right wheel for the material being ground and checking the grinder for damage before use. Proper maintenance procedures, such as wheel dressing and balancing, are also outlined to keep the equipment in good working condition and minimize risks.

Compliance with Regulations:

Many workplaces are required by law or industry standards to have SOPs for potentially dangerous equipment like bench grinders. Adhering to these procedures helps the organization remain compliant with occupational health and safety regulations.

Promoting Consistency:

A SOP ensures that all users operate the bench grinder in a consistent and safe manner, reducing the likelihood of accidents due to improper use. It standardizes the process, so even new or less experienced users can follow the same guidelines as seasoned operators.

Enhancing Efficiency:

By following a standardized procedure, operators can use the grinder more effectively and efficiently. Proper use of the tool extends the life of the equipment and ensures that work is completed accurately and safely.

An SOP for a bench grinder is an essential document that ensures safety, adherence to regulations, and operational efficiency in the workplace.