Plant and Equipment Risk Assessments

Plant and Equipment Risk Assessments (PERA)

Plant is a major cause of workplace death and injury in Australian workplaces. There are significant risks associated with using plant and severe injuries can result from the unsafe use of plant, including:

- limbs amputated by unguarded moving parts of machines

- being crushed by mobile plant

- sustaining fractures from falls while accessing, operating or maintaining plant

- electric shock from plant that is not adequately protected or isolated

- burns or scalds due to contact with hot surfaces, or exposure to flames or hot fluids.

Other risks include hearing loss due to noisy plant and musculoskeletal disorders caused by manually handling or operating plant that is poorly designed.

The Plant and Equipment Risk Management Forms and Safe Work Procedure templates have been designed as generic guides to assist workplaces with assessing plant risks and developing safe work procedures. These documents should be used as a guide only and do not mitigate the requirement to assess plant risks and develop safe work procedures that are appropriate for the plant within your environment.

Requirements under the WHS Act

Regulation 203: A person with management or control of plant at a workplace must manage risks to health and safety associated with the plant.

Regulation 34-38: In order to manage risk under the WHS Regulations, a duty holder must:

- identify reasonably foreseeable hazards that could give rise to the risk

- eliminate the risk so far as is reasonably practicable

- if it is not reasonably practicable to eliminate the risk, minimise the risk so far as is reasonably practicable by implementing control measures in accordance with the hierarchy of control

- maintain the implemented control measure so that it remains effective

- review, and if necessary revise, risk control measures so as to maintain, so far as is reasonably practicable, a work environment that is without risks to health and safety.

Keeping Records

Regulation 237: A person with management and control of plant must keep a record for plant that requires design or item registration, including records of all tests, inspections, maintenance, commissioning, decommissioning, dismantling and alterations of the plant.

The JSEAsy Plant and Equipment Register which includes a service and repair log is and excellent way to to comply with this requirement.

The Risk Management Process

From the Managing the risk of Plant in the Workplace Code of Practice:

Identifying hazards involves finding all of the things and situations that could potentially cause harm to people. Hazards associated with plant generally arise from:

- The plant itself. For example, hazards associated with a forklift would include hazards relating to its mobility, its electrical, hydraulic and mechanical power sources, its moving parts, its load-carrying capacity and operator protection.

- How and where the plant is used. The forklift, for example, may have hazards arising from the kind of loads it is used to lift, the size of the area in which it is used and the slope or evenness of the ground.

A plant and equipment risk assessment is important because it helps to identify potential hazards and risks associated with the use of plant and equipment in the workplace and to implement controls to reduce the risk of injury or damage. It also helps to ensure that the plant and equipment are used safely and that the risks associated with their use are minimized.

All versions of the JSEAsy Environmental Health and Safety (EHS) software come preloaded with several Plant and Equipment Risk Assessments for various items of plant and equipment. Using the JSEAsy safety management software you can easily create additional PERAs to build an endless library of PERAs.

You can purchase individual PERAs as standalone documents from us as well.

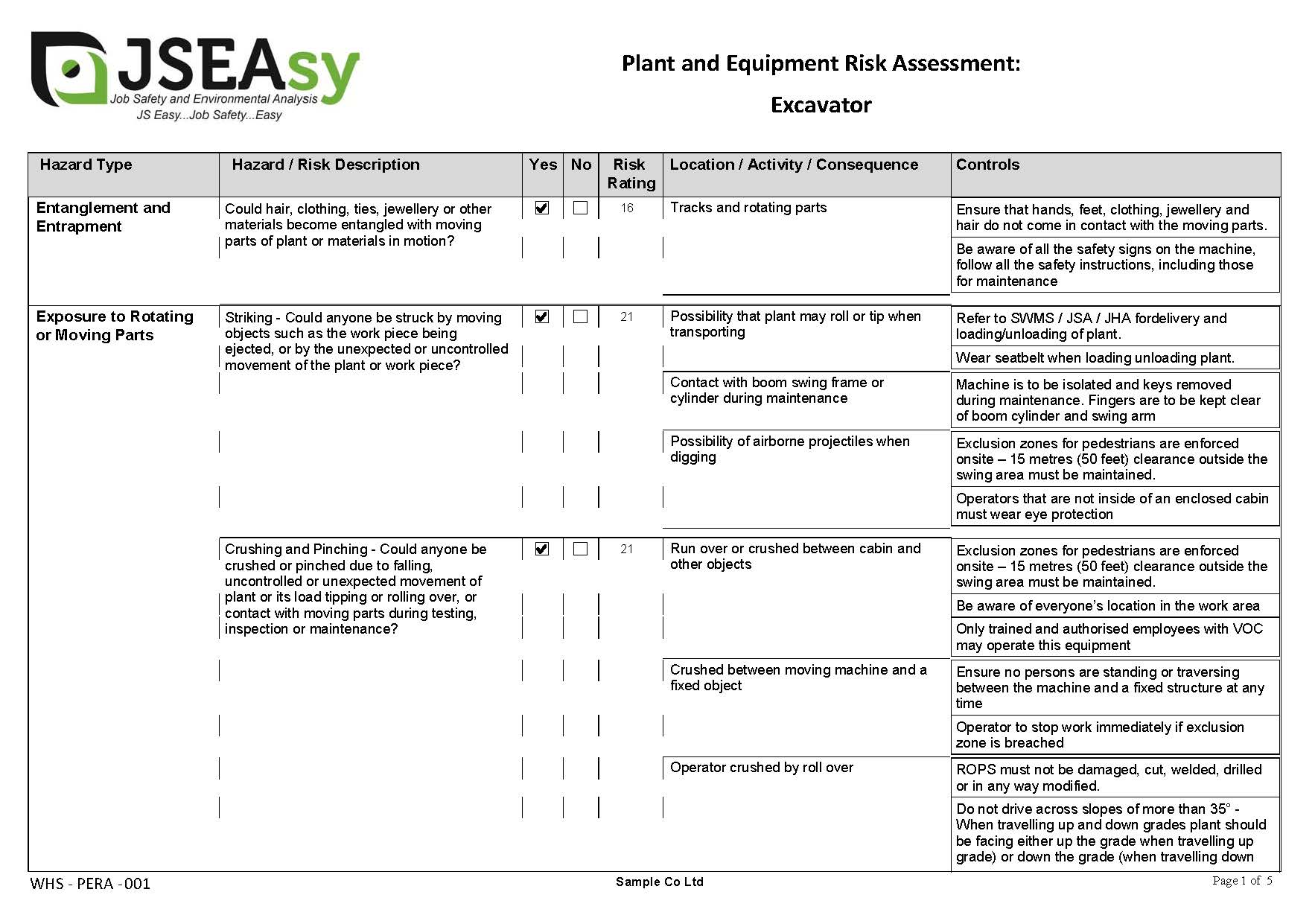

PERA 001 Excavator

PERA 002 Render Mixing Pump

PERA 003 Telehandler

PERA 004 Forklift

PERA 005 Diesel-Powered High-Pressure Water Jet

PERA 006 Diesel walk-behind floor saw

PERA 007 Petrol-Powered Masonry Ring Saw

PERA 008 Petrol-Powered Masonry Chainsaw

PERA 009 Electric masonry wall saw

PERA 010 Core Drill

PERA 011 Petrol-Powered Quick Cut Demolition Saw

PERA 012 Water Truck

PERA 013 Tipper/ Dump Truck

PERA 014 Hook-Lift Truck

PERA 015 Crawler Mounted Hydraulic Drill Rig

PERA 016 Prime Mover and AAA Step Deck Trailer

PERA 017 Prime Mover and Semi Side Tipper

PERA 018 Rigid Truck with Loading Crane

PERA 019 Tandem Trailer Water Cart

PERA 020 Articulated Electric Mini Loader

PERA 021 Twin Drum Roller / Road Roller

PERA 023 Compact Track Loader/ Posi-Track Loaders

PERA 024 EPS Hot Melting Machine

PERA 025 Scissor Lift