Managing Plant and Equipment with JSEAsy EHS Software

Risk Assessment Software for Plant and Equipment

Managing plant and equipment safety is a critical responsibility for every business, contractor, and operator. Without a reliable system in place, the risk of accidents, downtime, and non-compliance with WHS regulations increases dramatically. That’s where JSEAsy Risk Assessment Software for Plant and Equipment comes in—helping businesses across Australia and beyond simplify compliance, improve safety culture, and save time.

Whether you manage a fleet of vehicles, heavy machinery, or specialised tools, JSEAsy provides the tools to create, manage, and share professional safety documentation with ease.

Why Businesses Need Risk Assessment Software for Plant and Equipment

Every piece of equipment carries risks—from forklifts and prime movers to hand tools and electrical appliances. Identifying these hazards and putting effective controls in place is not only a legal requirement but also essential to protecting your workers and business reputation.

Traditional paper-based systems are slow, inconsistent, and prone to error. By switching to risk assessment software, you benefit from:

Consistency: Standardised templates ensure no critical hazards are overlooked.

Efficiency: Generate professional documents in minutes instead of hours.

Accessibility: Store and access all safety records in one centralised system.

Compliance: Stay aligned with AS/NZS ISO 31000 Risk Management Standards and WHS regulations.

Audit readiness: Produce documented evidence of risk assessments instantly when regulators or clients request them.

Key Features of JSEAsy Risk Assessment Software

JSEAsy is more than just a risk assessment tool—it’s a complete safety management software designed to streamline plant and equipment management.

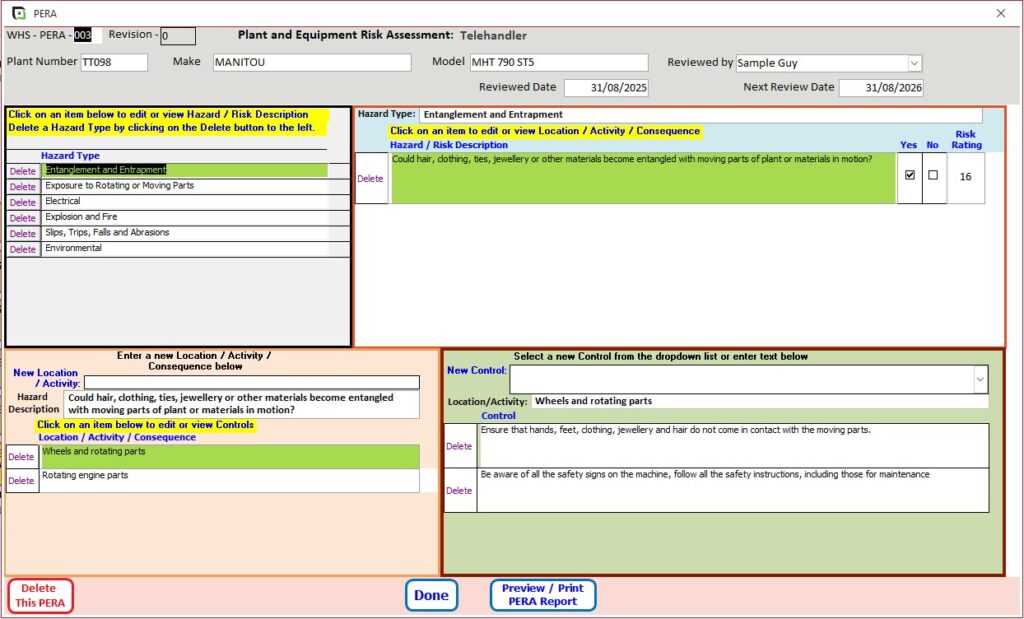

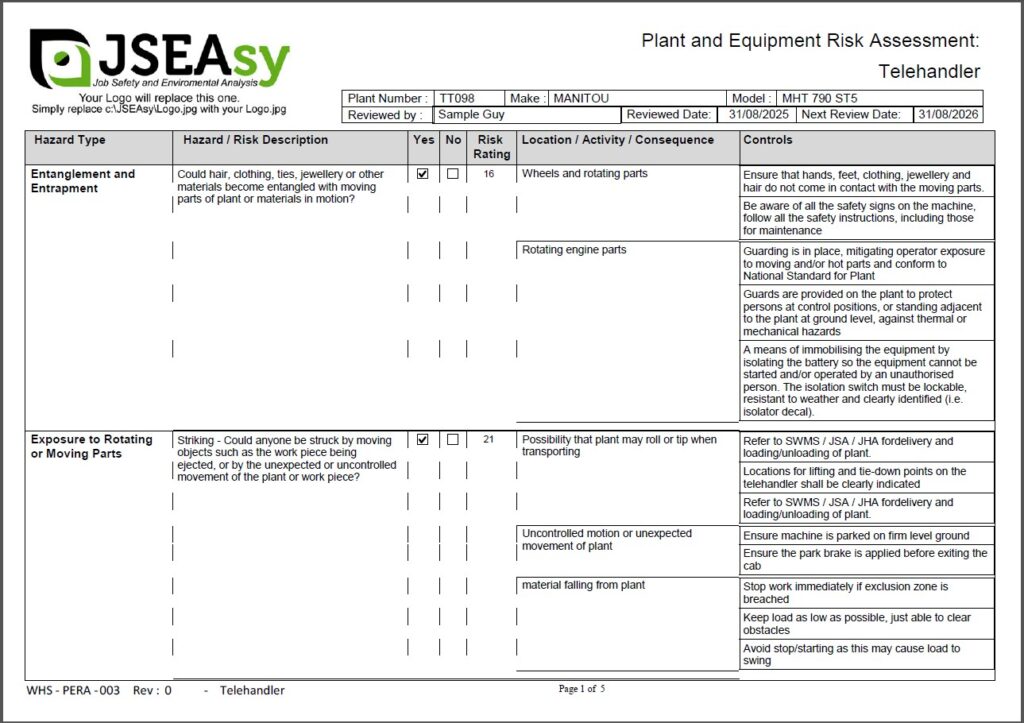

Plant and Equipment Risk Assessments (PERAs)

Inline withe Managing Plant Code of Practice, detailed Plant and Equipment Risk Assessments (PERAs) for machinery, vehicles, and tools. Each template includes:

Hazard identification

Risk ratings

Control measures

Safe operating procedures

All documents can be exported as professional PDF files ready for sharing with your workforce or clients

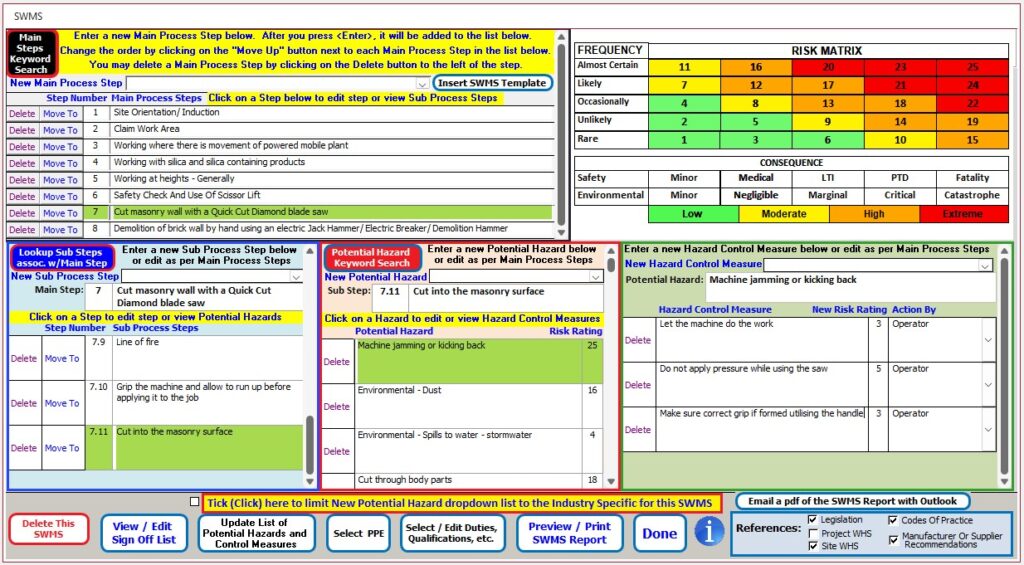

Safe Work Method Statements (SWMS)

Create your PERAs in line with your Safe Work Method Statements (SWMS), ensuring that all risks are addressed in job-specific procedures. This creates a seamless process from plant and equipment management to on-site work activities.

Customisation Made Easy

Every business is unique. With JSEAsy, you can customise:

Company branding and logos

Job-specific risk factors and hazards

Control measures tailored to your site or industry

This flexibility ensures your documentation always reflects your business practices.

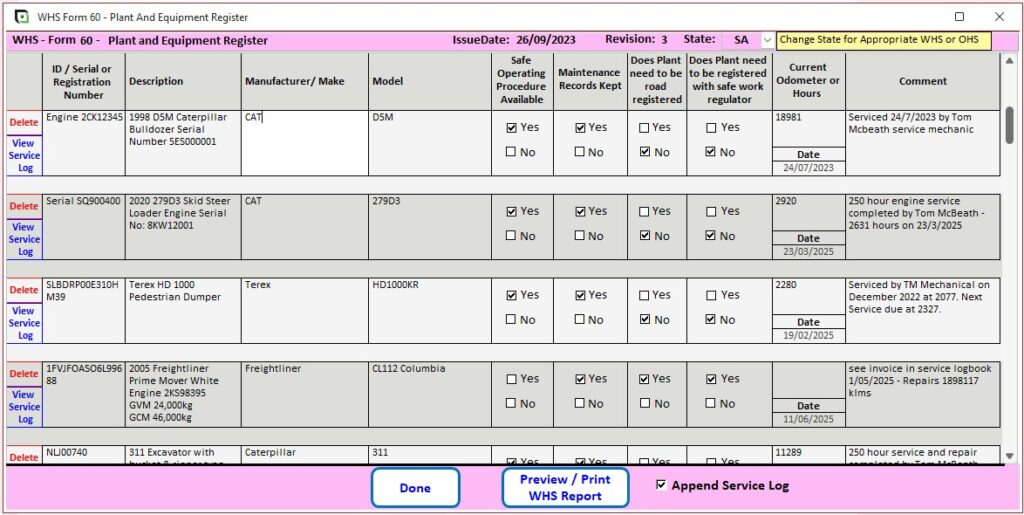

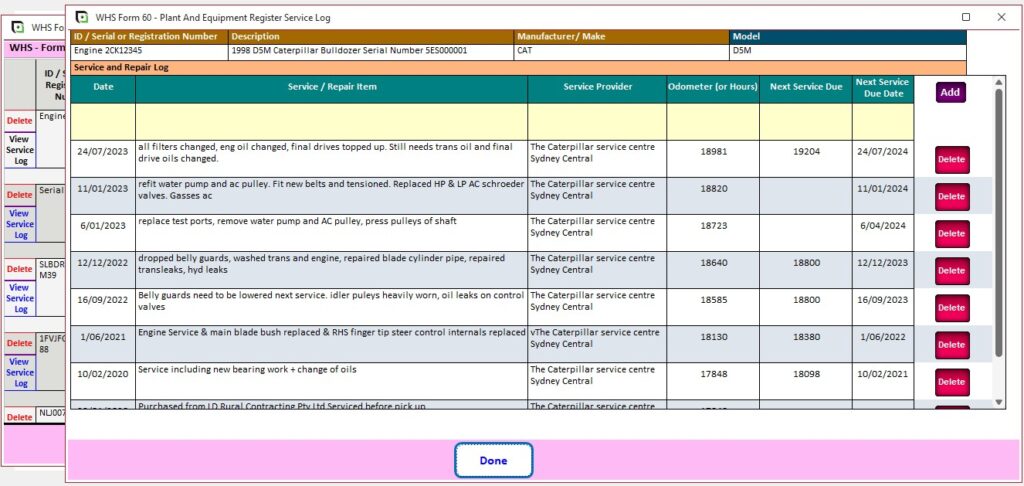

Centralised Plant and Equipment Register

Keep track of all your assets in one place. JSEAsy allows you to:

Record plant and equipment details

Track inspection and maintenance schedules

Set reminders for servicing and compliance checks

Reduce the risk of using unsafe or out-of-date equipment

Project Plant And Equipment Register

From the job form in the JSEAsy safety management software you can generate site related WHS forms including a Project Plant And Equipment Register. In this site register form, you can pull items of plant and equipment from your master Plant and Equipment Register

Instant PDF and Digital Access

Generate and distribute safety documents instantly. Your team can access them on-site, ensuring that risk assessments are not just “paperwork” but practical tools actively used in daily operations.

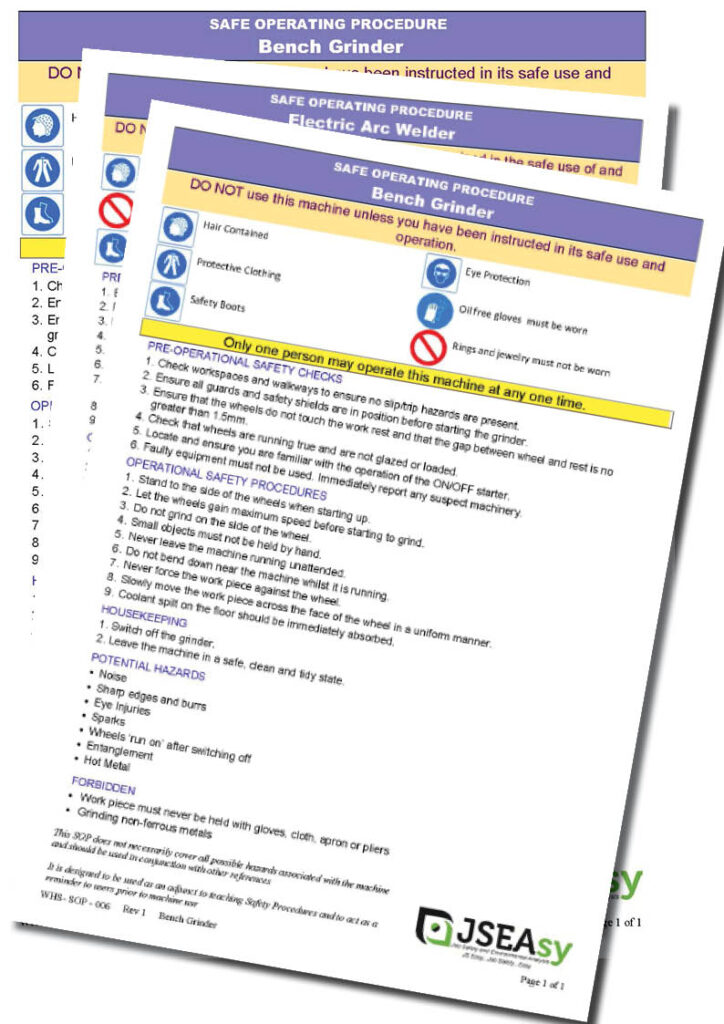

Safe Operating Procedures (SOP)

Safe Operating Procedures (SOP) or Safe Work Procedures (SWP), sometimes referred to as Standard Operating Procedures, are essential for guiding individuals on how to safely operate machinery or equipment. These operational documents outline the safest and most efficient way to complete a task, perform an operation, or use a machine/tool.

SOPs summarise the risks involved in a work task and provide a step-by-step guide with appropriate risk control measures to ensure tasks are carried out safely.

Plant Inspections

There are a number of inspection forms included in the JSEAsy Environmental Health and Safety Software. Some of these are directly related to Plant and Equipment:

- WHS Form 67 Mobile Plant Daily checklist

- WHS Form 88 Truck and Trailer daily checklist

- WHS Form 103 Mobile Elevating Work Platform (MEWP) Familiarisation Checklist

Emergency Response plans

There are a number of ERPs included in the JSEAsy safety management software. Some of these are directly related to Plant and Equipment:

- WHS Form 41 EWP Emergency Response Procedure

- WHS Form 61 Portable Ladder Inspection

- WHS Form 68 Trench and Excavations Incident Emergency Response Procedure

- WHS Form 69 Vehicle or Mobile Plant Rollover Emergency Response Procedure

- WHS Form 108 Lift and Elevator Emergency Response Procedure

Benefits of Using JSEAsy for Plant and Equipment Management

When you implement JSEAsy Risk Assessment Software for Plant and Equipment, you gain benefits that extend across safety, productivity, and compliance:

Save Time: What used to take hours with spreadsheets and word processors can now be done in minutes.

Boost Safety Culture: Workers are more likely to follow safety procedures when they are clear, consistent, and easy to understand.

Ensure Compliance: Stay up to date with WHS legislation and industry standards.

Reduce Costs: Avoid fines, reduce downtime, and minimise accidents through proactive risk management.

Scalable for All Business Sizes: From small contractors with a single machine to large enterprises managing hundreds of assets, JSEAsy adapts to your needs.

Who Can Benefit from JSEAsy?

JSEAsy software is trusted by businesses across industries, including:

Construction companies managing cranes, excavators, and powered tools

Transport operators with fleets of trucks, prime movers, and trailers

Manufacturing facilities running production lines and specialised machinery

Mining and resources businesses with high-risk plant and equipment on-site

Facilities managers ensuring compliance across multiple sites

If your business uses plant or equipment, JSEAsy can help you manage the risks.

Compliance and WHS Made Simple

Australian workplaces are bound by strict Work Health and Safety (WHS) regulations, requiring employers to demonstrate that they have identified hazards, assessed risks, and implemented control measures.

If you’re involved in plant design, manufacture, supply, operation, storage, demolition and disposal, you have work health and safety (WHS) duties.

With JSEAsy, you can:

Generate WHS-compliant risk assessments

Maintain an auditable record of safety practices

Prove due diligence during inspections or audits

Standardise safety documents across your organisation

This ensures that you don’t just “tick the box” for compliance—you embed safety into every aspect of plant and equipment management.

Why Choose JSEAsy?

Unlike generic safety software, JSEAsy is purpose-built for plant and equipment management. With over 20 years of development, the platform combines deep safety expertise with user-friendly technology.

Proven in industry: Trusted by contractors, SMEs, and large organisations.

Australian-focused: Aligned with local WHS laws and standards.

Scalable: Suitable for businesses of all sizes.

Support included: Access tutorials, help guides, and responsive customer support.

Start Managing Plant and Equipment Risks Today

Every day that plant and equipment operate without proper risk assessments increases the chance of accidents, downtime, and compliance issues. By investing in JSEAsy Risk Assessment Software for Plant and Equipment, you take a proactive step towards safer, more efficient operations.

Get started with JSEAsy Today and see how simple safety management can be.

Frequently Asked Questions (FAQs)

Q: Can I customise the risk assessments for my own business?

Yes. JSEAsy allows you to edit, add, or remove hazards and controls so your documents reflect your specific workplace needs.

Q: Does the software cover Safe Work Method Statements (SWMS)?

Absolutely. You can access Plant and Equipment Risk Assessments directly with SWMS and SOPs to create complete, compliant safety packages.

Q: Is JSEAsy suitable for small businesses?

Yes. Whether you manage one machine or an entire fleet, JSEAsy scales to fit your requirements.

Q: How do I access my documents?

All risk assessments and safety documents are created and stored in the software. They can be downloaded instantly as PDFs or stored digitally for on-site access.

Final Word

Managing plant and equipment safety doesn’t have to be overwhelming. With JSEAsy Risk Assessment Software for Plant and Equipment, you can create professional, compliant, and effective risk assessments in minutes. Protect your workers, meet WHS obligations, and streamline your business with one simple tool.

👉 Try JSEAsy Today – the smarter way to manage plant and equipment safety.