Safety Observer / Spotter (Safety Watch) – Roles, Responsibilities and Training

A Safety Observer—also commonly called a Spotter or Safety Watch—is a dedicated person who monitors high-risk work and warns workers or plant operators of hazards that may not be visible to them. On many construction, civil and maintenance sites, using a competent safety observer is a practical control measure that helps prevent incidents involving mobile plant, excavations, elevated work platforms (EWPs), and overhead power lines.

At JSEAsy, we provide practical, site-ready WHS documentation to help businesses define spotter requirements clearly, train workers, verify competency, and demonstrate compliance with Canadian OHS expectations.

What is a Safety Observer / Spotter?

A Safety Observer is a person who is assigned to observe a task continuously and communicate hazards immediately so the work can be stopped or adjusted before an incident occurs.

A spotter is particularly effective when:

- The operator’s view is restricted (plant cabs, EWPs, tight access)

- Workers are exposed to crush zones or moving plant

- There is risk of contact with overhead services

- The work environment is changing (ground conditions, weather, traffic)

A key principle is that spotting is a dedicated duty—the spotter should not be distracted by secondary tasks.

When is a Spotter Required?

A spotter may be required whenever risk controls rely on continuous observation and active warning. Common examples include:

Excavation and Trenching Work

Spotters are used to help manage:

- Interaction between workers and mobile plant

- Exclusion zones around excavations

- Unplanned ground movement, slumping, cracking, or water ingress

- Working around underground services and potholing locations

- Safe placement of spoil piles and access/egress points

Elevated Work Platforms (EWP) and Working at Height

A ground-based spotter is often used when:

- The EWP travels or slews near structures, services, or edges

- There is risk of entrapment/crush zones during positioning

- Workers may pass beneath the EWP or within the work envelope

- Visibility is reduced due to site congestion, lighting, or obstacles

Working Near Overhead Power Lines

Spotters are commonly used to prevent:

- Plant, attachments, or loads entering minimum approach distances

- Unexpected line contact during slewing, lifting, or travel

- Changes in conditions (wind, load sway, uneven ground)

Work near overhead services should be planned with appropriate controls and may require additional approvals or permits depending on the site and network operator requirements.

Responsibilities of a Safety Observer / Spotter

Although duties vary by task, core responsibilities generally include:

- Maintain continuous visual observation of the work activity

- Monitor and protect exclusion zones and pedestrian separation

- Identify hazards outside the operator’s field of view

- Communicate clearly using agreed hand signals or radio protocols

- Confirm that the operator understands directions before movement begins

- Escalate issues immediately and stop work when unsafe conditions arise

- Monitor changing site conditions and advise the supervisor as required

What a Spotter Must NOT Do

A spotter cannot perform their job effectively if distracted. As a general rule, a spotter must not:

- Operate tools or perform other tasks while spotting

- Leave position without handing over to another competent spotter

- Assume the operator “can see it”

- Continue work when minimum distances or exclusion zones are at risk

A spotter should have clear authority to instruct an operator to stop and to escalate to the supervisor.

Competency, Training and Verification

A compliant approach is more than a toolbox talk. Best practice is a simple three-step model:

Awareness – Worker understands what a spotter is and when one is needed

Training – Worker receives task-specific instruction (excavation, EWP, electrical proximity)

Verification – Supervisor confirms competency on-site using a checklist/sign-off

JSEAsy templates support this process by providing clear role statements, practical controls, and evidence of training and competency.

Many businesses also formalise spotter duties in a dedicated procedure. JSEAsy provides WHS procedures and SOP Templates, including a Safety Observer SOP aligned with ISO 45001

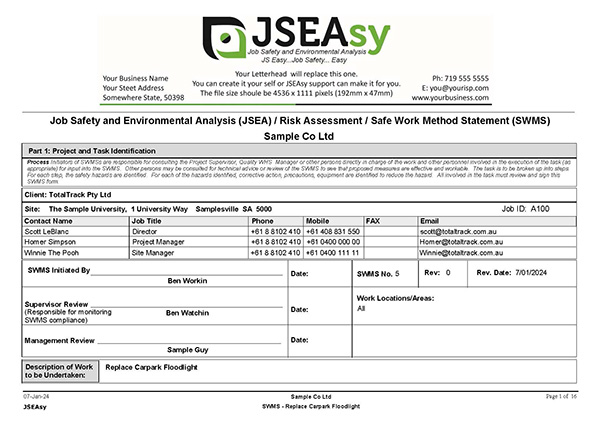

How to Document Spotter Requirements on Site

To demonstrate a structured WHS approach, spotter requirements should be documented in multiple places.

For higher-risk tasks, spotters should also be confirmed through formal permits such as excavation permit templates, or an electrical proximity permit, with the spotter named and communication methods documented.

SWMS: Include a clear “Spotter / Safety Observer” control section

Permits: Add a tick-box and named spotter field (excavation, electrical proximity, high-risk tasks)

SOP / Procedure: Define responsibilities, communication rules, and competency requirements

Training Records: Keep toolbox records, training attendance and competency sign-offs

This creates a defensible evidence trail if you are audited, investigated, or need to demonstrate due diligence.

JSEAsy Spotter Documentation and Training Tools

JSEAsy provides practical, editable WHS templates that help businesses implement a consistent spotter system, including:

Spotter / Safety Observer SOP (ISO 45001 aligned)

SWMS templates for excavations, EWPs and overhead power lines

Toolbox talk content for team briefings

Competency verification checklists for supervisor sign-off

Permit wording templates (excavation and electrical proximity)

One-page quick guide suitable for printing and laminating

If you manage contractors or multiple sites, these resources help standardise expectations and reduce reliance on informal “site knowledge.”

Need Help Implementing Spotter Controls?

If you want to improve plant–pedestrian separation, reduce service strike risk, or tighten EWP and electrical proximity controls, JSEAsy can help you build a clear, repeatable system with documentation that is easy for crews to follow.

Browse our Spotter / Safety Observer templates or contact us for help tailoring the documentation to your work type and jurisdiction.

Frequently Asked Questions

Is a safety observer the same as a spotter?

In most workplaces, yes. “Safety observer,” “spotter,” and “safety watch” are often used interchangeably, but duties should always be defined in your SWMS/SOP.

Can a spotter do other tasks at the same time?

As a general rule, no. If the spotter is distracted, the control is weakened. Spotting should be a dedicated activity.

Who has authority to stop work?

A spotter should have authority to stop work if an unsafe condition is developing, and to escalate immediately to the supervisor.