Essential Safety Measures for Working in a Commercial Kitchen

Effective Strategies for Controlling Hazardous Chemicals in a Commercial Kitchen

Controlling hazardous chemicals in a commercial kitchen is crucial for ensuring the safety of all employees and customers. Here’s a comprehensive approach:

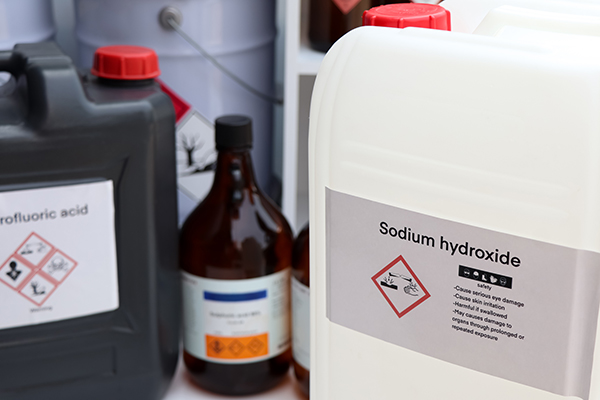

Proper Labeling and Storage

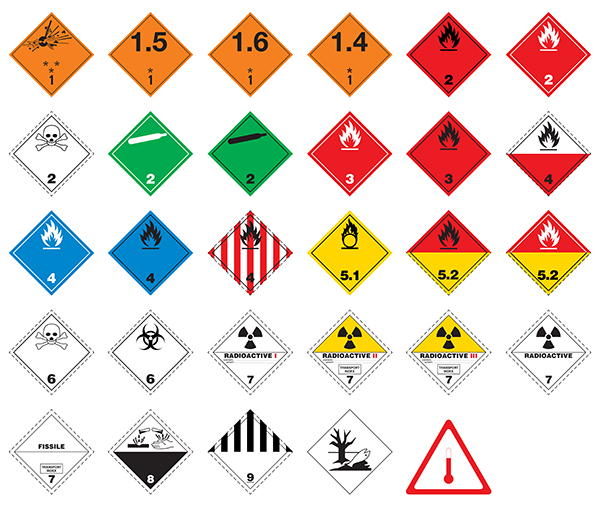

- Labeling: Ensure that all chemical containers are clearly labeled with their contents and hazard warnings. Use standardized labels that are easy to read and understand.

- Storage: Store chemicals in a designated area away from food preparation areas. Use locked cabinets or shelves that are clearly marked as containing hazardous chemicals.

- Separation: Store chemicals separately from food and food-related items to prevent cross-contamination.

Employee Training

- Hazard Communication: Train all employees on the risks associated with hazardous chemicals, including how to read labels and Safety Data Sheets (SDS).

- Proper Use: Instruct employees on the correct handling, usage, and disposal of chemicals, emphasizing the importance of never transferring chemicals into food containers.

- Emergency Procedures: Educate staff on emergency procedures in case of accidental ingestion, including first aid steps and whom to contact.

Safe Practices and Procedures

- Use of Personal Protective Equipment (PPE): Provide appropriate PPE (like gloves and masks) when handling hazardous chemicals to prevent accidental exposure.

- Workplace Hygiene: Implement strict hygiene practices, such as washing hands after handling chemicals and before touching food.

- Spill Management: Develop and enforce a protocol for managing chemical spills, including immediate cleanup and decontamination of affected areas.

Routine Inspections and Audits

- Regular Checks: Conduct regular inspections to ensure that chemicals are stored properly and that there are no signs of cross-contamination or improper handling.

- Audit Compliance: Periodically audit compliance with safety protocols and make adjustments as needed based on observed practices.

Limiting Chemical Access

- Restricted Access: Limit access to hazardous chemicals to trained personnel only. Use lockout/tagout systems where necessary.

- Control Dispensing: Implement controlled dispensing systems to ensure that only the necessary amount of chemicals is used and to reduce the risk of accidental exposure.

Substitution and Minimization

- Use Safer Alternatives: Where possible, replace hazardous chemicals with less harmful alternatives.

- Minimize Use: Use the smallest effective amount of chemicals to reduce the risk of exposure and contamination.

Emergency Response Planning

- First Aid Kits: Ensure that first aid kits are available and stocked with appropriate supplies for chemical exposure.

- Emergency Contacts: Clearly display emergency contact information, including poison control and local emergency services.

- Decontamination Stations: Have eyewash stations and emergency showers available in case of chemical splashes.

Documentation and Reporting

- Incident Reporting: Implement a system for reporting and documenting any chemical-related incidents, including near misses, to help prevent future occurrences.

- Review and Improve: Regularly review incident reports to identify patterns and improve safety protocols.

By combining proper training, strict storage procedures, routine inspections, and emergency preparedness, a commercial kitchen can significantly reduce the risk of accidental ingestion of hazardous chemicals.