Hierarchy of Controls

What Is the Hierarchy of Controls?

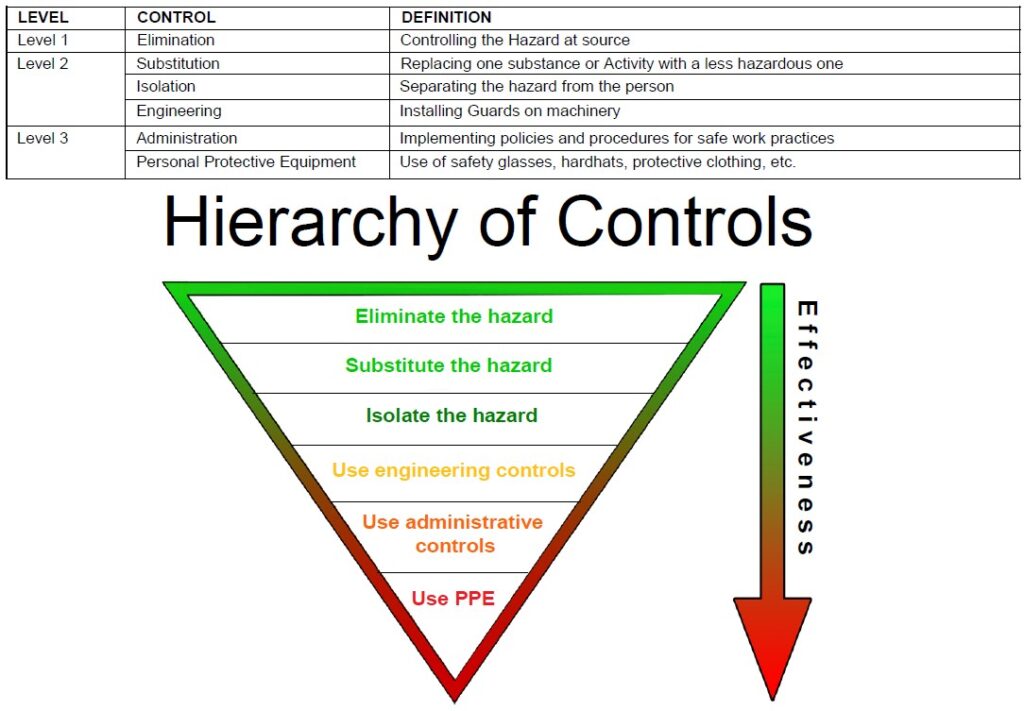

The hierarchy of control is a step-by-step approach to eliminating or reducing risks, and it ranks risk controls from the highest level of protection and reliability through to the lowest and least reliable protection.

They are arranged from the most to least effective and include elimination, substitution, engineering controls, administrative controls and personal protective equipment.

First, identify and assess the risks, then decide the best way to control them by applying the Hierarchy of Control as follows:

Eliminate hazards and risks

This is the highest level of protection and most effective control. Eliminating the hazard and the risk it creates is the most effective control measure. You must always aim to eliminate the risk, which is the most effective control. If this is not reasonably practicable, you must minimize the risk by working through the other alternatives in the hierarchy.

Elimination makes sure the hazard no longer exists. Examples:

• Ending the use of a hazardous material

• Doing work at ground level rather than at heights

• Stopping the use of noisy processes

Reduce the risk

Reduce the risk with one or more of the following controls:

Substitution

Substitute the risks with lesser risks Isolation, changing out a material or process to reduce the hazard. Examples:

• Switching to a less hazardous material

• Switching to a process that uses less force, speed, temperature, or electrical current.

Substitution is very effective but may not always be possible.

Isolation

Isolate people from the risks. The hazard is separated from the people at risk by isolating it. This can be done by restricting the hazard to a small area, effectively containing the risk within that space. Examples:

- Lockout/Tagout (LOTO): LOTO procedures are used to isolate energy sources (such as electrical, hydraulic, or pneumatic) during maintenance or repair work. Locks and tags prevent accidental activation of machinery while maintenance is ongoing.

- Quarantine Areas: In healthcare or laboratories, quarantine areas are used to isolate patients or samples with contagious diseases.

These controls do not rely on worker behavior and can be very effective.

Engineering

Reduce the risks through engineering changes or changes to systems of work. Preventing hazards from coming into contact with workers. Examples:

- Machine guards

- Installing ventilation systems to remove hazardous fumes.

- Guardrails

These controls do not rely on worker behavior and can be very effective.

Administrative controls

Use administrative actions to minimize exposure to hazards and to reduce the level of harm by changing the way people do work. Giving workers more information by providing workers with relevant procedures, training, or warnings. Examples:

- Implementing standard or Safe operating procedures (SOPS)

- Completing task specific risk assessments:

- Safe Work Method Statements (SWMS)

- Job Safety Analysis (JSA)

- Job Hazard Analysis (JHA)

These are less effective than elimination or engineering controls because they depend on human behavior.

Personal Protective Equipment (PPE)

Lowest level of protection and least reliable control. PPE includes clothing and devices to protect workers. Examples:

- Safety Glasses

- Hard Hats

- Safety Boots

- Hearing Protection

- Respirators

- Personal Fall protection equipment

- Protective clothing

This is the least effective method because it relies on proper usage and does not eliminate the hazard.