Handling Chemicals, Hazardous Substances & Dangerous Goods

Safe Handling of Chemicals & Dangerous Substances | JSEAsy Guidance on safely handling chemicals, hazardous substances and dangerous goods worldwide, including risk assessments, SDS, storage, and safety procedures.

Safe Handling of Chemicals, Hazardous Substances and Dangerous Goods

Managing chemicals, hazardous substances, and dangerous goods safely is a critical responsibility for workplaces worldwide. Improper use, storage, or disposal can result in serious injuries, health risks, fires, explosions, and environmental harm.

JSEAsy provides practical, internationally-relevant documentation to help organisations identify chemical hazards, assess risks, and implement effective controls to maintain a safe working environment.

What Are Chemicals, Hazardous Substances and Dangerous Goods?

Chemicals

Chemicals include any substance, mixture, or product used or generated at work, such as fuels, solvents, acids, cleaning agents, adhesives, paints, gases, and industrial chemicals.

Hazardous Chemicals / Substances

Hazardous chemicals are substances classified as posing health or physical risks. They may cause:

Acute or chronic health effects (toxicity, sensitisation, carcinogenicity)

Skin or eye irritation or burns

Long-term occupational illnesses

Examples include solvents, pesticides, corrosives, silica-based products, and isocyanates.

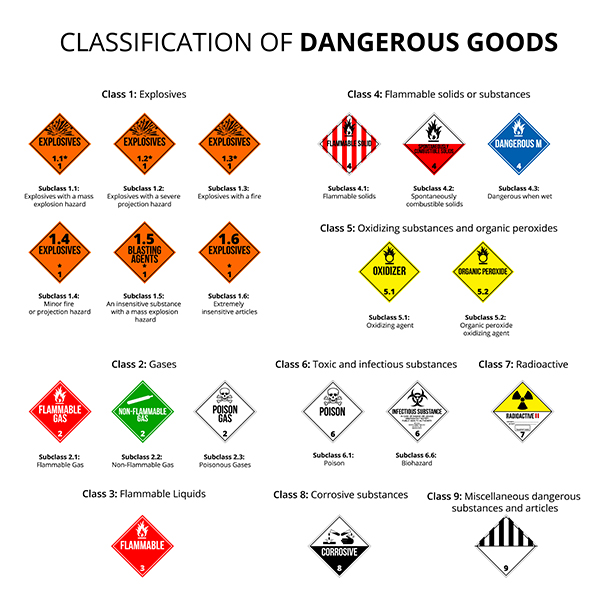

Dangerous Goods

Dangerous goods are chemicals that present immediate physical hazards, including:

Flammability

Explosiveness

Oxidising properties

Corrosivity

Acute toxicity

They are classified by internationally recognised hazard classes and require careful storage, labelling, and segregation.

Key Risks Associated With Handling Hazardous Chemicals and Dangerous Goods

Common risks when handling hazardous chemicals and dangerous goods include:

Inhalation of fumes, vapours, mists, or dusts

Skin or eye contact causing burns or dermatitis

Fire or explosion from ignition of flammable substances

Chemical reactions from incompatible storage

Environmental contamination from spills or leaks

Improper disposal or uncontrolled releases

Without effective controls, these risks can lead to serious injuries, long-term health impacts, and business disruption.

Legal and Safety Obligations (International)

Workplaces must, where applicable:

Identify all chemicals used or stored

Assess and control exposure risks

Ensure chemicals are correctly labelled and accompanied by Safety Data Sheets (SDS)

Provide proper storage, segregation, and spill containment

Train workers in safe handling, emergency response, and PPE use

Implement emergency procedures for spills, leaks, fires, and exposures

Best Practices for Managing Chemical Risks

1. Identification and Classification

Identify all chemicals in the workplace

Confirm hazard classifications and SDS

Document quantities, use, and storage

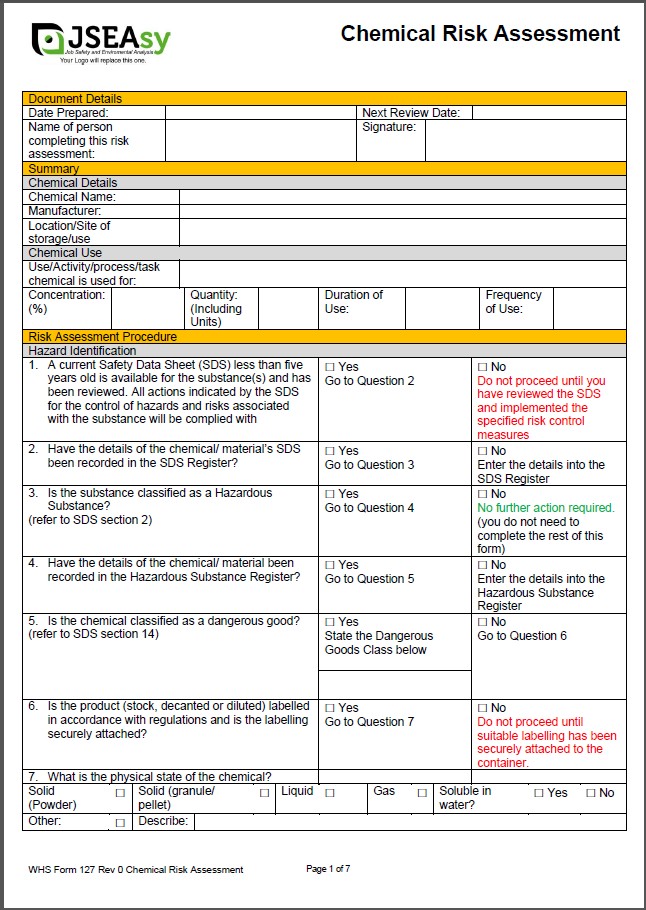

2. Risk Assessment

Assess exposure pathways (inhalation, skin contact, ingestion)

Evaluate quantities, frequency, and environmental factors

Consider storage, transport, and disposal risks

3. Control Measures

Apply the hierarchy of control:

Eliminate or substitute hazardous chemicals where possible

Use engineering controls (ventilation, bunding, closed systems)

Apply administrative controls (procedures, signage, permits)

Provide personal protective equipment (PPE)

4. Storage and Labelling

Store chemicals in approved containers and cabinets

Segregate incompatible substances

Maintain clear labelling and signage

Provide secondary containment as needed

5. Training and Supervision

Educate workers on hazards and SDS information

Train workers in handling, spill response, and emergency procedures

Supervise high-risk chemical tasks

6. Emergency Preparedness

Use appropriate spill kits

Provide eyewash stations and safety showers where required

Ensure fire protection and isolation controls

Implement incident reporting and investigation processes

How JSEAsy Supports International Workplaces

JSEAsy provides practical, editable documentation to support chemical safety worldwide, including:

- Hazardous chemical risk assessments

- Dangerous goods handling procedures

- Storage and segregation guides

- Spill response and emergency procedures

- Safe Work Method Statements (SWMS)

- Job Safety Analysis (JSA)

- Job Hazard Analysis (JHA)

- Registers and checklists aligned with international standards

Why Choose JSEAsy for Chemical Safety

Developed with international safety standards in mind

Practical, site-ready documentation

Easy to customise for specific operations

Supports compliance and due diligence obligations

Saves time while improving workplace safety

If your organisation handles chemicals, hazardous substances, or dangerous goods, having clear and compliant procedures is essential. JSEAsy helps you implement effective controls and demonstrate a structured approach to chemical safety management.

Industries and Workplaces We Support

Our chemical safety resources are suitable for:

Construction and civil engineering

Maintenance and facilities management

Manufacturing and industrial operations

Utilities and infrastructure projects

Workshops, depots, and warehouses

Any workplace using, storing, or transporting hazardous chemicals or dangerous goods

Frequently Asked Questions (FAQ)

What is the difference between hazardous chemicals and dangerous goods?

Hazardous chemicals pose health risks, while dangerous goods present immediate physical hazards like fire, explosion, or corrosion. Some chemicals may be classified as both.

Do I need a hazardous chemicals register?

Yes. Most international safety regulations require workplaces to maintain a register of hazardous chemicals, including current SDS.

When is a chemical risk assessment required?

Whenever hazardous chemicals are used, stored, or handled, especially if there is potential risk to health or safety.

What documents should I have for chemical safety?

Common documents include chemical risk assessments, hazardous chemical registers, SDS, storage and segregation procedures, spill response plans, and method statements.

Are dangerous goods subject to additional requirements?

Yes. Dangerous goods are subject to specific classification, storage, segregation, labelling, and emergency response requirements depending on quantity and hazard class.